氣動密封件材質物性表 Table of Pneumatic Seal Materials

|

Material材質

item項目

|

Standard material標準材質

|

||||

|

|

NBR

|

NBR

|

NBR

|

NBR

|

|

|

Normality 常態

|

JIS Hs硬度(JIS Hs)

|

75±5

|

80±5

|

85±5

|

90±5

|

|

Min tensile strength kg/cm²抗拉強度(kg/cm²)最小

|

160

|

165

|

165

|

170

|

|

|

Min elongation 延伸率(%)最小

|

250

|

200

|

200

|

150

|

|

|

Compressive deformation test 壓縮變形測試

|

Temperature time Hrs. 溫度(℃)時間(Hrs.)

|

100℃/70

|

100℃/70

|

100℃/70

|

100℃/70

|

|

Max deflection 最大變形量(%)

|

20

|

20

|

20

|

25

|

|

|

Material feature材質特性

|

Available for oil, without and dry air

適用于給油、無給油以及干燥空氣的情況下

|

||||

氣動液壓元件部分

|

Application

用途

|

NO. 編號

|

Form形狀

|

Material 材質

|

Application range 適用范圍

|

||

|

Temperature 溫度

|

Pressure 壓力

|

Speed 速度

|

||||

|

For piston

活塞用

|

APA

|

|

NBR

|

-35~120

|

10

|

1.0

|

|

APP

|

|

NBR

|

-20~80

|

10

|

1.0

|

|

|

PPY

|

|

NBR

|

-20~80

|

10

|

1.0

|

|

|

For inching

緩動用

|

AEI

|

|

NBR

|

-30~120

|

16

|

1.0

|

|

For axle

軸用

|

PDU

|

|

NBR

|

-20~80

|

10

|

1.0

|

|

PRY

|

|

NBR

|

-20~80

|

10

|

1.0

|

|

|

For dust removing

除塵用

|

SDR

|

|

NBR

|

-25~100

|

-

|

1.0

|

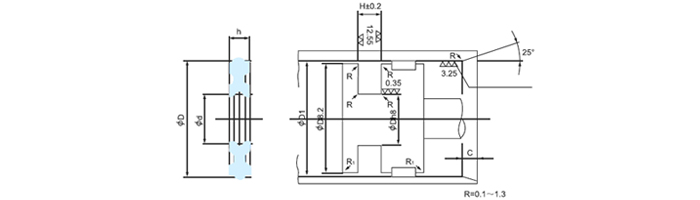

APA尺寸表 APA Size Table

| D |

d |

h |

D |

d |

D1 |

H |

C |

|

10 |

5.4 |

1.7 |

10 |

5.4 |

9.7 |

1.8 |

1 |

|

12 |

7.4 |

1.7 |

12 |

7.4 |

11.7 |

1.8 |

1 |

|

15 |

10.4 |

1.7 |

15 |

10.4 |

14.7 |

1.8 |

1 |

|

16 |

11.4 |

1.7 |

16 |

11.4 |

15.7 |

1.8 |

1 |

|

20 |

14 |

2.2 |

20 |

14 |

19.5 |

2.4 |

1.5 |

|

25 |

17 |

3 |

25 |

17 |

24.5 |

3.2 |

2 |

|

30 |

22 |

3 |

30 |

22 |

29.5 |

3.2 |

2 |

|

32 |

24 |

3 |

32 |

24 |

31.5 |

3.2 |

2 |

|

38 |

30 |

3 |

38 |

30 |

37.5 |

3.2 |

2 |

|

40 |

32 |

3 |

40 |

32 |

39.5 |

3.2 |

2 |

|

44 |

36 |

3 |

44 |

36 |

43.5 |

3.2 |

2 |

|

50 |

40 |

3.8 |

50 |

40 |

49.5 |

4 |

2.5 |

|

56 |

46 |

3.8 |

56 |

46 |

55.5 |

4 |

2.5 |

|

60 |

50 |

3.8 |

60 |

50 |

59.5 |

4 |

2.5 |

|

63 |

53 |

3.8 |

63 |

53 |

62.4 |

4 |

2.5 |

|

70 |

55 |

5.7 |

70 |

55 |

69.4 |

6 |

3 |

|

75 |

60 |

5.7 |

75 |

60 |

74.4 |

6 |

3 |

|

80 |

65 |

5.7 |

80 |

65 |

79.4 |

6 |

3 |

|

85 |

70 |

5.7 |

85 |

70 |

84.4 |

6 |

3 |

|

90 |

75 |

5.7 |

90 |

75 |

89.4 |

6 |

3 |

|

95 |

80 |

5.7 |

95 |

80 |

94.4 |

6 |

3 |

|

100 |

85 |

5.7 |

100 |

85 |

99.4 |

6 |

3 |

|

110 |

95 |

5.7 |

1410 |

95 |

109.3 |

6 |

3 |

|

115 |

100 |

5.7 |

115 |

100 |

114.3 |

6 |

3 |

|

120 |

105 |

5.7 |

120 |

105 |

119.3 |

6 |

3.5 |

|

125 |

110 |

5.7 |

125 |

110 |

124.3 |

6 |

3.5 |

|

130 |

115 |

5.7 |

130 |

115 |

129.3 |

6 |

3.5 |

|

140 |

125 |

5.7 |

140 |

125 |

139.3 |

6 |

3.5 |

|

150 |

135 |

5.7 |

150 |

135 |

149.3 |

6 |

3.5 |

|

160 |

140 |

7.7 |

160 |

140 |

159.3 |

8 |

5 |

|

175 |

155 |

7.7 |

175 |

155 |

174.3 |

8 |

5 |

|

180 |

160 |

7.7 |

180 |

160 |

179.3 |

8 |

5 |

|

200 |

180 |

7.7 |

200 |

180 |

199 |

8 |

5 |

|

250 |

230 |

7.7 |

250 |

230 |

249 |

8 |

5 |

|

300 |

280 |

7.7 |

300 |

280 |

299 |

8 |

5 |